Background

The NASA Engineering and Safety Center (NESC) has reviewed flight, ground test, and published data on ultraviolet-induced degradation of silicone based thermal control coatings. Analysis has shown, for at least one silicone coating, that bake-out plays an important role in ultraviolet (UV) degradation, indicating that UV interaction with paint volatiles, and not the structural material, is the primary source of coating discoloration.

Discussion

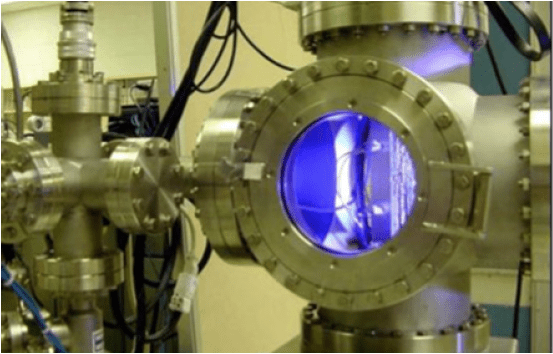

Spacecraft temperature is primarily determined by the absorptivity and emissivity of the vehicle’s coating. Absorptivity is the fraction of the sun’s irradiance that is absorbed, and emissivity determines the amount of infrared power that is emitted. The combination of these properties, along with additional heat from internal sources and other external radiation sources, determines the spacecraft’s thermal environment. Choosing an appropriate coating, referred to as a thermal control coating, is key to keeping the vehicle within a desired temperature range. However, these coatings can degrade, (i.e., darken), in low earth orbit (LEO), primarily due to solar UV exposure, complicating the choice of coating. Zinc-oxide (ZnO) scatterers in a silicate binder are among the most stable white coatings but suffer from poor adherence. Replacing the silicate with organic silicone improves paint mechanical properties, but optical property measurements of UV exposure stability for ZnO-silicone coatings have been widely divergent. This led to a request that the NESC resolve the variations to better predict the stability of specific ZnO-silicone coatings in LEO. Testing of coupons began in FY25 and will complete in FY26.

Many silicone-based thermal control coatings have been evaluated in ground simulation chambers and tested in space since the mid-1960s [ref 1, 2], demonstrating a wide range of UV degradation rates, sometimes for the same formulation. Ground testing a particular ZnO-silicone coating in two different facilities yielded degradation rates that differed by more than a factor of 6. This is similar to variations seen in a round-robin test of ground UV exposure facilities in the 1960s [ref. 2] and casts doubt as to the usefulness of ground testing to predict flight performance. In this case, consideration of the differences between the two ground tests along with partial retesting, pointed to the presence of volatiles as the source of the difference. In one facility, the samples were baked out prior to testing, removing most of the volatiles in the paint, but in the other facility the samples were not baked out. This indicated that the primary source of absorptivity change was UV interaction, not with the silicone substrate material, nor with the ZnO scatterers, but with the volatiles. In addition, the two facilities had different UV irradiance spectra, which may have contributed to the large degradation variation [ref.3].

A literature search was conducted and, surprisingly, only one paper was found that tested ZnO-silicone paint degradation with and without a prebake [ref. 1]. In this publication, paint S-31 without a bake-out was exposed to 1780 equivalent solar hours (ESH) of UV and saw a change in absorptivity of 0.02, but a sample that was baked at 260°C (500°F) for 1 hour and then exposed to 1780 ESH saw only a change of 0.006. In a second case, two S-33 samples were exposed to 4170 ESH, both with a one hour 150°C prebake out and one with an additional one hour 260°C prebake. The one with the single bake-out saw an absorptivity change of 0.02 and the one with the additional bake-out saw a change of only 0.011, comparable to the “best zinc oxide…silicate paint.”

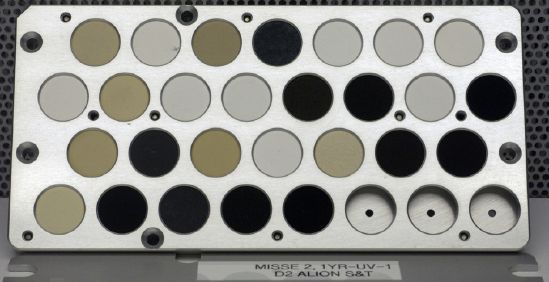

Testing of ZnO-silicone paints has been conducted on the Materials International Space Station experiment (MISSE), [ref. 4], showing a similar reduction in UV degradation for samples that were baked out prior to flight and those that were not. In MISSE-19, a sample of a ZnO-silicone paint that was baked out showed a net change in absorptivity of 0.011 (Wake position) versus 0.27 for a sample of the same paint in the Zenith position that was not baked out. There is positional variation that may have contributed to this difference, but the removal of volatiles is a likely contributor.

Finally, spacecraft testing of the same ZnO-silicone paint has shown very low UV degradation over extended periods in LEO which is interesting given that the paint on the spacecraft is not baked out. Aerodynamic heating on ascent is insufficient to remove the volatiles, however, surface temperatures while in orbit are sufficient. On the spacecraft, the paint covers an insulative, micrometeor protective layer allowing the paint to heat in sunlight (unlike the MISSE samples that are painted on aluminum disks mounted to an aluminum tray). This heating in orbit provides a nearly continuous bake-out, removing not only residual volatiles, but newly formed volatiles created by UV induced decomposition of longer chain molecules. Comparing outgassing data to the bake-out conditions further supports the proposition that volatiles within the paint, and not the binder or scatterers, discolor under solar UV exposure. Indicating that prebake or, in-flight continuous baking, is a key requirement for long duration performance of a specific family of ZnO-silicone based thermal control coatings.

References

1. Ref. Zerlaut, G. A., Y. Harada, and E. H. Tompkins. “41. Ultraviolet Irradiation of White Spacecraft Coatings.” In Symposium on Thermal Radiation of Solids, vol. 55, p. 391. Scientific and Technical Information Division, National Aeronautics andSpace Administration, 1965.

2. Arvesen, J. C., C. B. Neel, and C. C. Shaw. “44. Preliminary Results From a Round- Robin Study of Ultraviolet Degradation of Spacecraft.” In Symposium on Thermal Radiation of Solids, vol. 55, p. 443. Scientific and Technical Information Division, National Aeronautics and Space Administration, 1965.

3. ARVESEN, J. “Spectral dependence of ultraviolet-induced degradation of coatings for spacecraft thermal control.” In 2nd Thermophysics Specialist Conference, p. 340. 1967.

4. Kenny, Mike, Robert McNulty, and Miria Finckenor. “Further Analysis of Thermal Control Coatings on MISSE for Aerospace Applications.” In National Space and Missile Materials Symposium, no. M09-0535. 2009.