Each year, Aviation Week (AW) Network recognizes a limited number of innovators who achieve extraordinary accomplishments in the global aerospace arena with AW’s prestigious Laureate Award. These innovators represent the values and vision of the global aerospace community and change the way people work and move through the world.

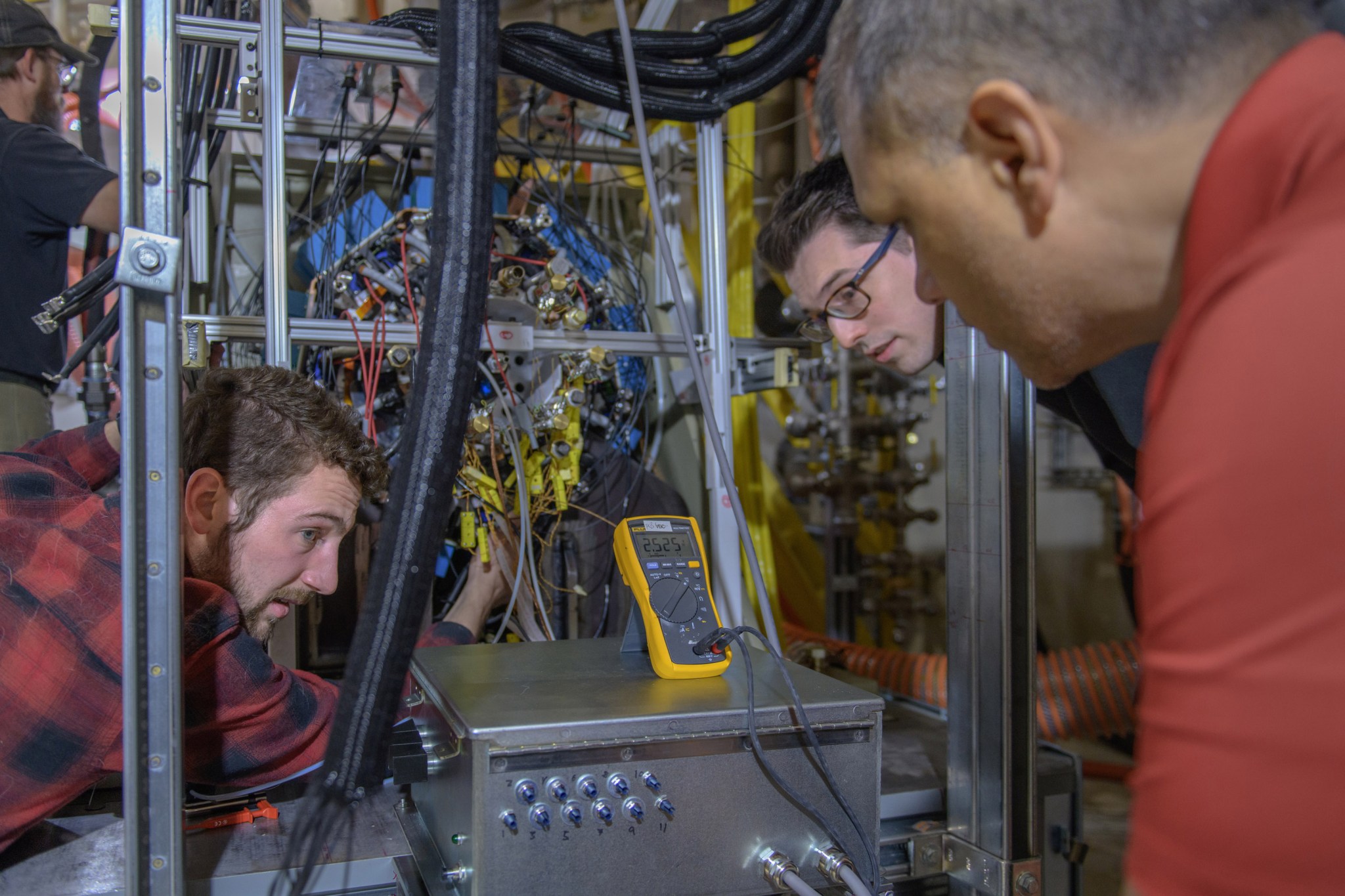

On March 6, NASA’s Glenn Research Center accepted an AW Laureate Award in commercial aviation for NASA’s Electric Aircraft Testbed (NEAT) located at NASA Glenn’s Neil Armstrong Test Facility in Sandusky, Ohio. NEAT allows government, industry, and academia to collaborate and conduct testing of high-powered electric powertrains, which generate power and propel aircraft forward. The goal is to transform commercial flight by creating more sustainable, fuel-efficient commercial aircraft.

NEAT enables ground testing of cutting-edge systems prior to experimental flight testing. As a result, researchers can troubleshoot issues that only occur at altitude and improve them earlier in the design cycle, which both accelerates the path to flight and makes it safer.

A number of “firsts” have been accomplished in the electric aircraft testbed.

- NASA and GE Aerospace completed the first successful ground tests of a high-power hybrid electric aircraft propulsion system at simulated altitude in 2022.

- A megawatt-class electric machine was tested at NEAT by a university team led by The Ohio State University and the University of Wisconsin, under NASA’s University Leadership Initiative.

- Under the Electrified Powertrain Flight Demonstration project, magniX tested its high-power megawatt-class powertrain with a goal to achieve approximately 5% reduced fuel use.

- Systems tested at NEAT from General Electric and magniX will be flown on modified passenger aircraft currently being reconfigured for flight testing.