Research traveling to the International Space Station aboard NASA’s SpaceX 33rd commercial resupply mission includes testing 3D bioprinting of an implantable medical device, observing behavior of engineered liver tissues, examining microgravity’s effects on bone-forming cells, and additional 3D printing of metal in space. The SpaceX Dragon spacecraft is scheduled to launch to the orbiting laboratory in late August.

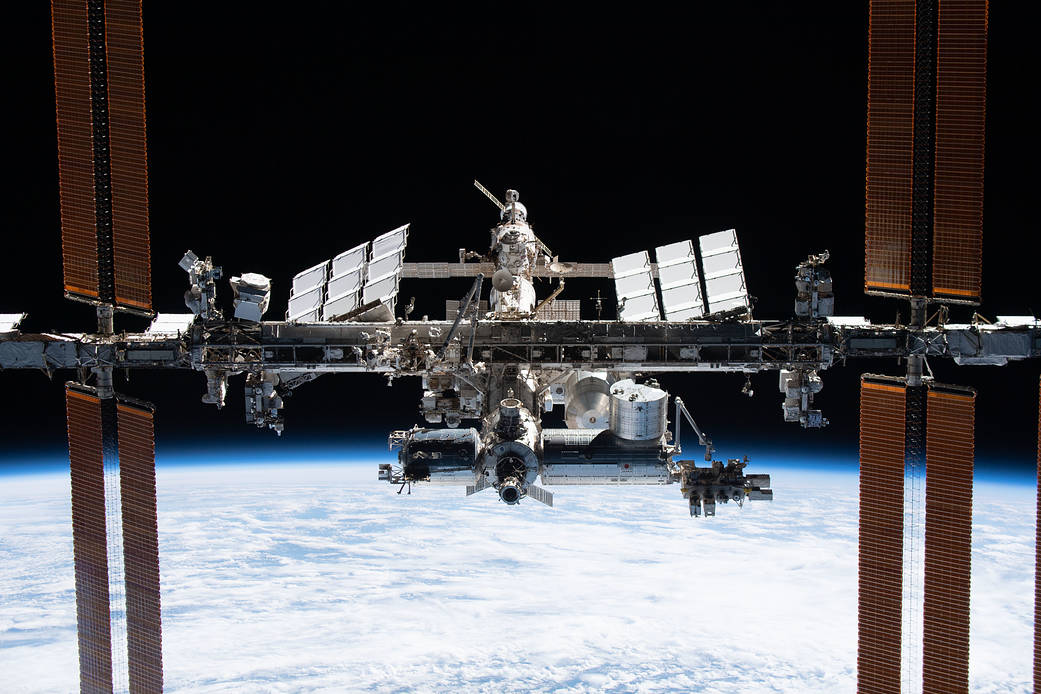

For nearly 25 years, the International Space Station has provided research capabilities used by scientists from over 110 countries to conduct more than 4,000 groundbreaking experiments in microgravity. Research conducted aboard the space station advances future space exploration – including missions to the Moon and Mars – and provides multiple benefits to humanity.

Read more about some of the latest investigations headed to the orbiting lab.

Better nerve bridge

Scientists are creating an implantable device in microgravity that could support nerve regrowth after injuries. The device is created through bioprinting, a type of 3D printing that uses living cells or proteins as raw materials.

Traumatic injuries can leave a gap between nerves, and existing treatments have limited ability to restore nerve function and may result in impaired physical function. A bioprinted device to bridge the nerve gap could accelerate recovery and preserve function.

“On this mission, we plan to print up to 18 of the implants and anticipate using them in preclinical studies on the ground in 2026 and 2027,” said Jacob Koffler, principal investigator at Auxilium Biotechnologies Inc in San Diego. Tissues bioprinted in microgravity may be higher quality than those made on Earth and results could support future manufacturing of medical devices in space for crew members on space missions and patients on Earth.

Bioprinted tissues with blood vessels

Researchers plan to bioprint liver tissue containing blood vessels on the ground and examine how the tissue develops in microgravity. Results could help support the eventual production of entire functional organs for transplantation on Earth.

A previous mission tested whether this type of bioprinted liver tissue survived and functioned in space, according to James Yoo, principal investigator at the Wake Forest Institute of Regenerative Medicine in Winston-Salem. This round could show whether microgravity improves development of the bioprinted tissue.

“We are especially keen on accelerating the development of vascular networks in the tissue,” Yoo said. Vascular networks produce the blood vessels needed to keep these tissues functional and healthy.

Blocking bone loss

A study of bone-forming stem cells in microgravity could provide insight into the basic mechanisms of the bone loss astronauts experience during space flight.

Researchers identified a protein in the body called IL-6 that can send signals to stem cells to promote either bone formation or bone loss. This work evaluates whether blocking IL-6 signals could reduce bone loss during spaceflight.

“If we are successful, the compound also can be evaluated for the treatment of conditions associated with bone loss on Earth, such as osteoporosis and certain types of cancers,” said Abba Zubair, principal investigator at the Mayo Clinic in Florida.

Space printing goes metal

As mission duration and distance from Earth increase, resupply becomes harder. Additive manufacturing or 3D printing could be used to make parts and dedicated tools on demand, enhancing mission autonomy.

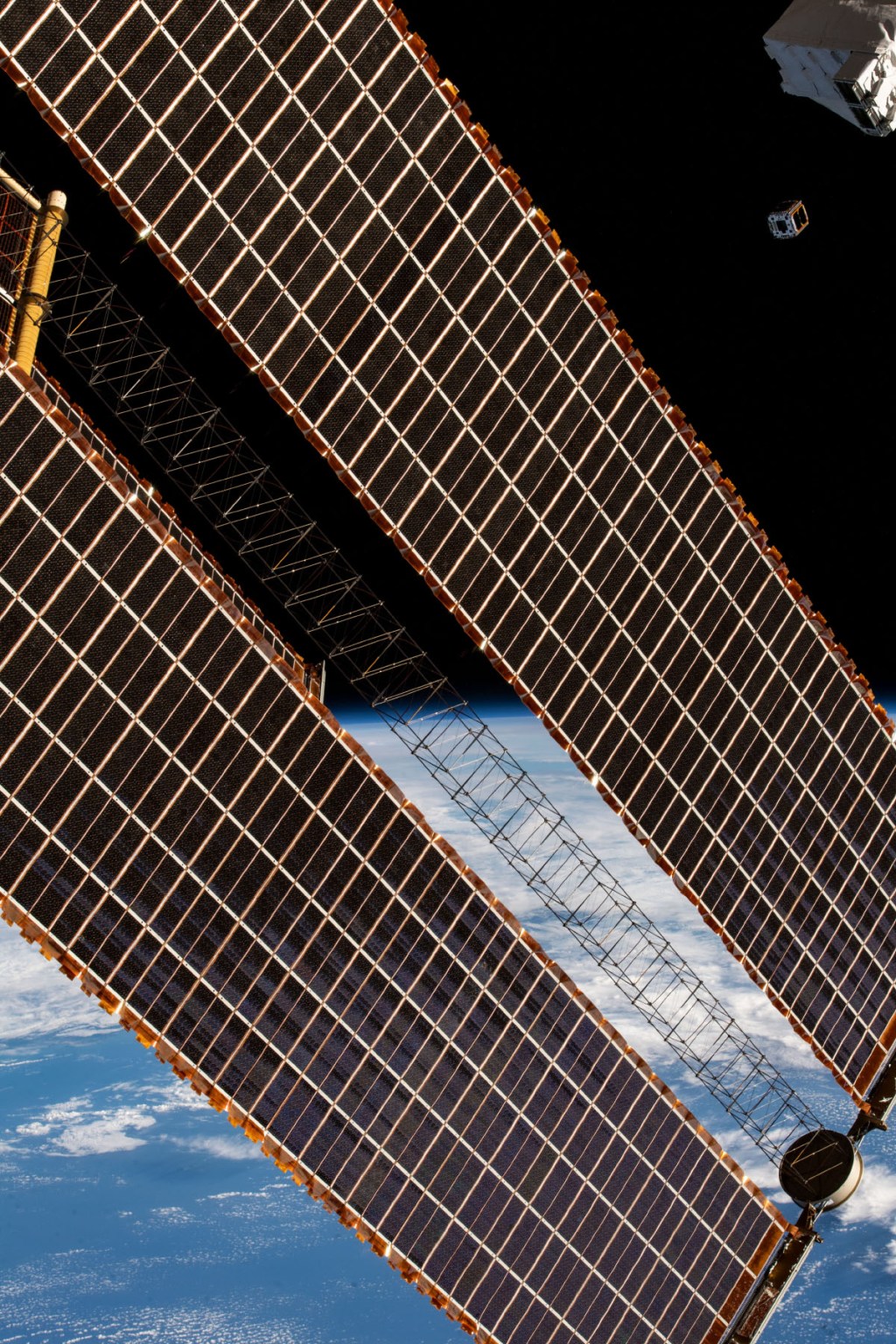

Research on the space station has made great strides in 3D printing with plastic, but it is not suitable for all uses. The ESA (European Space Agency) Metal 3D Printer investigation builds on recent successful printing of the first metal parts in space.

“We’ll print several small cubes using different strategies to help determine the optimal approach for metal printers in space,” said Rob Postema, ESA technical officer. Quality of the space-printed items will be compared against reference prints made on the ground.

This investigation is a continuation of ESA’s efforts to develop in-space manufacturing and materials recycling capabilities. The ESA investigation team includes Airbus Defence and Space SAS and the User Support Centre CADMOS in France.

Download high-resolution photos and videos of the research mentioned in this article.

Learn more about the research aboard the International Space Station at: